Introduction: The Integration Imperative

Every minute of delay in today’s supply chains means lost revenue and frustrated customers. Supply chain connectivity isn’t just about moving goods—it’s about moving data with the same speed and reliability. When systems can’t communicate, you’re facing a business crisis, not just a technical problem.

Global supply chains now span dozens of partners and thousands of daily transactions. The enterprises that thrive have mastered seamless integration—connecting systems so data flows effortlessly from procurement to delivery. Two dominant approaches achieve this: EDI integration and API-first architecture. They couldn’t be more different in philosophy and execution.

This isn’t “old versus new.” Both power billions in daily commerce. Understanding when to use each can make or break your digital strategy.

What is EDI? Strengths and Limitations

Electronic Data Interchange (EDI) has powered supply chain connectivity for four decades. EDI integration enables businesses to exchange standardized documents—such as purchase orders, invoices, shipping notices—directly between systems without human intervention. It’s a universal translator speaking in precisely formatted messages.

EDI uses established standards like ANSI X12 and EDIFACT. When your system generates a purchase order, EDI translates it into a standardized format, transmits it via secure channels like AS2 or VAN networks, and delivers it to your supplier’s system for automatic processing. No emails, no calls, no manual entry.

EDI’s Enduring Strengths

Where EDI Shows Its Age

What is API-first Architecture? Benefits and Challenges

API-first architecture represents a fundamentally different philosophy. Systems expose functionality and data through Application Programming Interfaces—controlled access points through which other systems request information or trigger actions in real-time. It’s the difference between mailing letters (EDI) and having live conversations (API).

An API-first approach means building supply chain systems with integration as the primary design principle. When customers place orders, API calls instantly check inventory across warehouses, reserve stock, calculate shipping, and update systems—all in milliseconds.

The API Advantage

The Challenges You Can’t Ignore

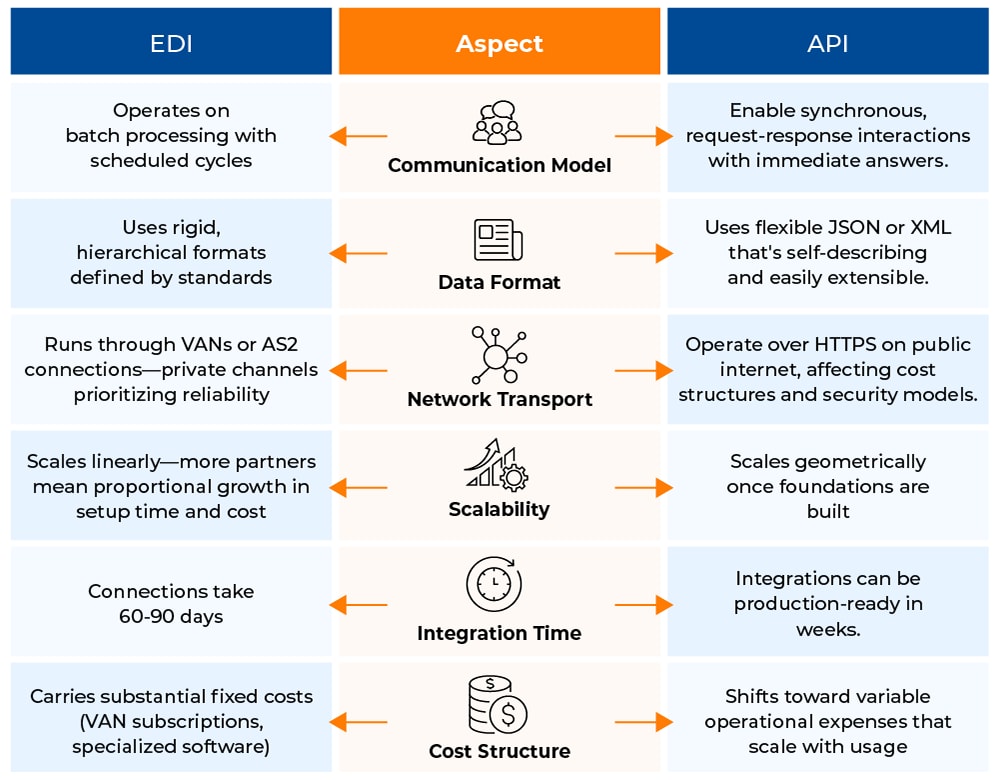

Key Differences Between EDI and API

When to Use EDI vs API

Conclusion: Hybrid Integration is the Future

The EDI versus API debate misses the point. The real question isn’t which to choose—it’s how to strategically combine both for resilient, agile supply chains.

EDI isn’t disappearing. It’s too embedded in global commerce and too reliable for high-volume, compliance-heavy transactions. But APIs represent the future—real-time visibility, rapid onboarding, and AI-driven automation.

Winning enterprises build hybrid integration platforms: robust EDI for established relationships and regulatory needs, complemented by API layers for innovation and agility. This approach delivers the best of both worlds—reliability and compliance from EDI, speed and flexibility from APIs.

EdgeVerve AI Next Supply Chain Integration solution operationalizes this hybrid strategy. It unifies standardized EDI transactions with real-time API orchestration, creating a single integration fabric that’s pragmatic for today and ready for tomorrow.

What sets it apart? AI-driven intelligence. The platform learns from transactional patterns, detects anomalies, and recommends optimal routing—EDI when compliance matters, APIs when speed is critical. It augments governance with automated policy checks and enriches integration with predictive ETAs, inventory risk signals, and smart retries.

Ready to take your supply chain integration to the next level? Explore EdgeVerve AI Next Supply Chain Integration Solution.