In today’s fast-paced and interconnected world, traditional supply chain management practices are being challenged like never before. The need to adapt and evolve has become paramount for businesses aiming to stay competitive and deliver exceptional customer experiences.

Amidst the shifting landscape of international trade dynamics, global retail corporations will be left grappling with the aftermath of trade tensions between two major economies. The sudden imposition of tariffs will disrupt their established supply chains, forcing them to confront the daunting task of rebuilding and adapting to a new business reality.

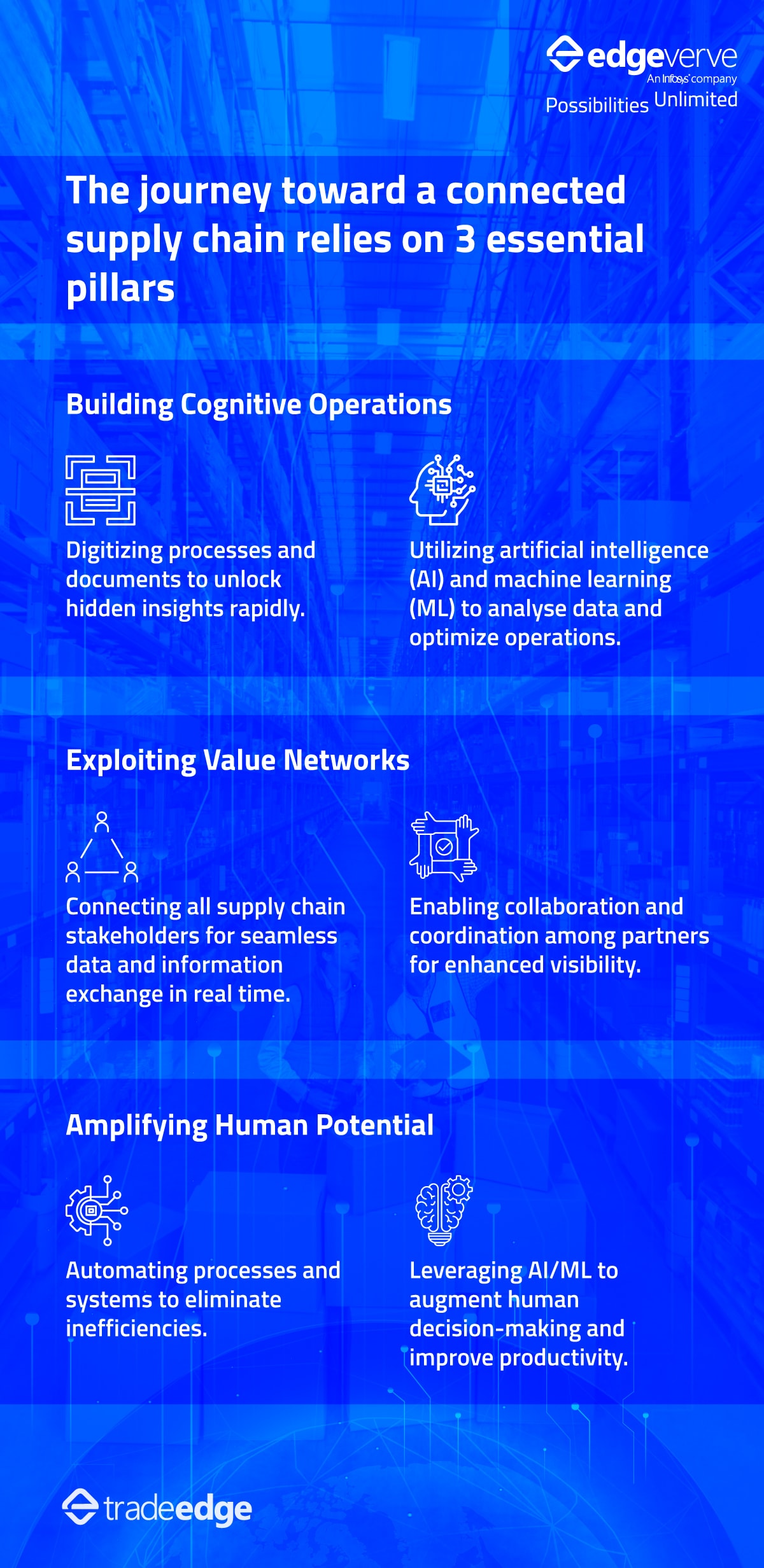

While the supply chain often remains inconspicuous during seamless operations, recent economic events have laid bare the fragility inherent in the existing paradigm. Organizations have learned to swiftly pivot in response to evolving market demands, capitalizing on cutting-edge technologies to attain unparalleled visibility and insight.

However, in the face of this evolving landscape, key questions arise:

How can the system evolve to enable predictive suggestions for real-time problem resolution? How can cognitive technology facilitate the development of a truly interconnected and resilient supply chain?

Before addressing these questions, Let’s examine the root causes and challenges that underpin the need for transformation.

The Challenges of Traditional Supply Chains:

Rethinking Customer Centricity in the Supply Chain

The pursuit of customer-centricity within the supply chain presents its own set of challenges, particularly when it comes to bridging the digital technology gap between small and large businesses.

While larger companies have witnessed a significant 45% increase in digital technology investments, their smaller counterparts have only managed a modest 25% rise. This discrepancy in investment limits the ability of small businesses to embrace customer-centric practices, putting them at a disadvantage in today’s competitive landscape.1

Moreover, the lack of data harmonization poses another obstacle, impeding visibility and timely insights. Information silos created by unsynchronized data across value chain partners hinder organizations’ understanding of the customer journey and their ability to respond promptly to evolving customer demands and preferences.

The onset of the pandemic has further exacerbated the challenges. With more than 60% of global consumers shifting their purchasing behaviors to prioritize convenience and value, the supply chain must grapple with the fragmentation of demand driven by the rapid growth of online commerce. This unpredictability makes it increasingly challenging to gauge the scale of success for supply chain operations.

In the face of these hurdles, businesses must adapt and transform their supply chains to thrive in the evolving landscape. By embracing innovative strategies and leveraging emerging technologies, organizations can forge a path toward customer-centric supply chains that are responsive, agile, and poised to meet the ever-changing needs of today’s dynamic marketplace.

Overcoming Data Silos for Timely Action

In the realm of supply chains, the adage “A chain is only as strong as its weakest link” holds true. The effectiveness of a supply chain relies heavily on the seamless flow of information across its various components.

However, when data is trapped in silos, it hampers timely action and decision-making, hindering supply chain planning and incurring high integration costs.

By proactively eliminating data silos and fostering a culture of collaboration and information sharing, organizations can transform their supply chains into agile ecosystems capable of withstanding the complexities and challenges of today’s business landscape.

Unlocking Demand Planning and Forecasting with Cognitive Computing

Around 86% of top-performing supply chain executives see cognitive computing as a game-changer for demand planning and forecasting. * Consequently, executives across industries actively embrace AI-driven automation to enhance decision-making and operational excellence, enabling them to build resilient supply chains.

Organizations can track and predict supply chain disruptions by leveraging AI and machine learning algorithms, providing unprecedented visibility into daily operations.

The goal is transitioning from traditional shipment demand-based forecasting to real-time demand signals, creating a value network united in this common objective.

For example, a renowned clothing company with a long-standing legacy and a global presence of over 3,000 brand-dedicated stores prioritized data-driven decisions to enhance consumer experiences.

By harmonizing data from various sources and implementing unified processes for collecting secondary data, they achieved a remarkable 99% accuracy in secondary sales data, strengthening their position as a leading omnichannel retailer. *

A Glimpse into the Future: The Networked Supply Chain:

In the relentless pursuit of resilient and efficient supply chains, a new era dawns – one powered by connected intelligence. By fostering seamless collaboration, democratizing data access, and embracing user-friendly technology, the cognitive supply chain empowers businesses to fortify their supply and demand functions, unleashing unprecedented possibilities.

At the heart of this transformation lies comprehensive data integration across the ecosystem, where tangible use cases illustrate the exponential value that can be unlocked. One notable example showcases a global leader in the beverage industry, leveraging a collaborative demand network fulfillment platform to derive data-driven insights from their vast network of distributors.

This disruptive initiative yielded remarkable improvements, including an outstanding 40-50% increase in distributor data accuracy, a substantial 15-20% reduction in stock-out scenarios, and an impressive 8-10% enhancement in case fill rates.* Fuelling these advancements was the platform’s intuitive dashboard, providing enhanced visibility that empowered businesses to proactively identify alternative sources of supply and confidently navigate the ever-changing market landscape.

As the future unfolds, the networked supply chain paves the way for a new era of collaboration, innovation, and resilience.

By embracing the power of connected intelligence, businesses can rewrite the rules of supply chain management, shaping a future where efficiency, agility, and customer-centricity converge harmoniously.

Conclusion:

The future of supply chain management lies in harnessing the power of AI-driven automation. By doing so, organizations can unlock real-time visibility, predictive insights, and enhanced decision-making capabilities. This empowers them to optimize order fulfilment, strengthen market connectivity, and drive effective sales strategies.

With visionary leadership and a relentless pursuit of operational excellence, businesses can position themselves for success in the dynamic and ever-evolving business landscape. By cultivating resilience, fostering efficiency, and embracing sustainable growth practices, they can shape a future where the transformative potential of cognitive supply chains becomes a reality.

Let us step boldly into this future, where innovation and intelligence converge, and together, we can shape a world where supply chains thrive and businesses flourish. The future belongs to those who dare to embrace the transformative power of cognitive supply chains. The future is ours to shape!

References: