The global economic waste crisis is quickly approaching critical mass. Resource shortages, rising raw material prices, and steadily eroding biospheres have firmly debunked the wisdom of a linear economy. And waste management and manufacturing will likely play key roles in the drive toward circular economic policies. Many manufacturers have fully embraced Industry 4.0 in terms of digitalization, but waste collection, recycling, and disposal have noticeably lagged. What kind of impact can the digitalization of waste management have? And why is it fundamental to building a circular economy? Let’s explore that in this article.

To policymakers, industrialists, and citizens worldwide, the writing on the wall has never been more obvious – the linear economy is no longer a viable model for economic progress. It creates an enormous amount of waste and drains significant resources via the handling and disposal of said waste. For instance, many major and minor municipal centres worldwide allocate 10% – 40% of their budget to solid waste management alone2.

Creating a closed-loop system of economic inputs and outputs is not new. The concept of the ‘circular’ economy surfaced as far back as the 1960s, although it only gained real traction among world governments in the early 2000s3. With current economic systems using the ‘take, make, waste’ cycle, increasingly scarce economic resources are irrevocably lost to landfills. The inter-mixing and degradation of materials make resource recovery nearly impossible.

The Need For A Circular Economy

Why should waste management companies care about creating a circular economy? Well, for one, it offers them the chance to transform from collection and disposal agents to raw material producers, substantially increasing the value of their products and services. Secondarily, the value created offsets the costs of processing highly volatile and hazardous waste, leading to greater profits and lowered costs at scale.

To policymakers, industrialists, and citizens worldwide, the writing on the wall has never been more obvious – the linear economy is no longer a viable model for economic progress. It creates an enormous amount of waste and drains significant resources via the handling and disposal of said waste. For instance, many major and minor municipal centres worldwide allocate 10% – 40% of their budget to solid waste management alone.

Over the next two decades, the amount of waste generated annually is expected to nearly double. Still, there has been little scalable change in waste management processes and protocols. According to surveys, while 60% of waste management first use an ERP platform, less than 13% have connected it to their CRM, service provider systems, or a more significant waste management ecosystem. The same research reveals that while 40% of firms have implemented digital vehicle tracking, only 7% use technology to track containers7.

Traditional waste management methodologies are woefully inadequate in coping with the uptick in global garbage creation and actualising the vision of a circular economy8.

Is Digital Transformation Truly Necessary For Waste Companies?

The waste management industry is home to a highly competitive landscape beset by challenges on multiple fronts. An example is pricing is the critical differentiator in developing an advantage over industry peers and the primary raw materials market.

On the one hand, the total cost of reclamation and recycling fluctuates with changes in operational and input costs (fuel price surges, attrition-induced training costs, compliance costs, etc.). In contrast, on the other, market prices for secondary raw materials can also vary. When the cost of producing recycled materials surpasses the market value of those goods themselves, waste companies are forced into a position where they must raise prices to retain margins. As a result, buyer interest in the secondary raw materials market can often be significantly reduced.

Like many enterprises today, waste companies’ processes can be grouped under two broad umbrellas – tactical and strategic. While the former is primarily operational and logistical, the latter involves profitability assessments, market positioning, growth planning, futureproofing, etc. Aligning these processes with the principles of a circular economy will involve significant organizational redesign and optimization. A key example lies in AI-powered value stream mapping – where the necessary information and resource flow to create a product in optimal takt time are mapped out to eliminate overproduction, waiting time, production complexity, logistical inefficiencies, and defects. Used in conjunction with algorithmic market analysis, this sort of digitization can rapidly turn waste companies into highly profitable materials producers.

On the same note, waste companies tend to be asset-heavy, often owning fleets and processing facilities. These assets lock up a tremendous amount of working capital by any measure.

A lighter, leaner waste management sector would involve a degree of fragmentation within the industry. A single organization focuses on a few competencies and is entrenched within an ecosystem of service providers across the value chain. To create the necessary value to support a circular economy, these ecosystems need to be supported by an efficient network of communication, commerce and collaboration platforms that ensure seamless, transparent data access to multiple stakeholders. This integrated ecosystem also makes mergers and acquisitions within the industry easier and faster to process, resulting in less overall industry downtime and more efficient waste reclamation.

- Primary Challenges In Waste Management

-

• Poor talent management, high attrition rates, and high labour costs.

-

• Economic stagnation and inflation reduce disposable income and waste generation, which in turn affects waste company revenues

-

• Asset-heavy working model limits capital availability

-

• Inefficient mapping, routing, and collection models

-

• Lack of segregation induces higher TCO and lower margins on reclaimed/recycled material

-

• Frequent litigation costs alongside complex compliance requirements

-

• Environmental degradation due to poor waste management practices

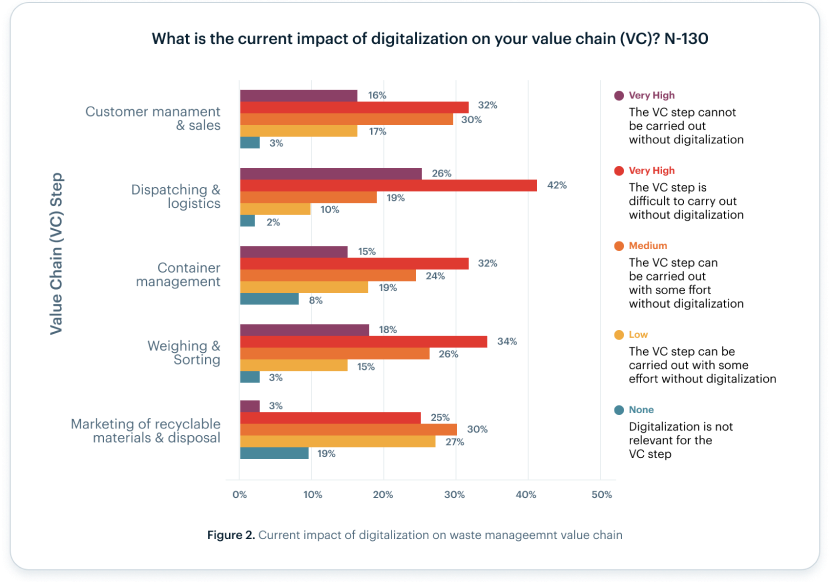

Mapping Out The Impact Of Digitalization

The digitalization movement is quickly becoming ubiquitous across nearly every industry and has impacted and evolved much of our day-to-day existence in social, economic, political, and environmental spheres. Waste management is no exception.

By optimizing input and output factors across multiple fronts, including collection, sorting, processing, and strategic planning, digital tech can make the waste management industry much more efficient and eco-friendlier. At the same time, these technologies lower the cost and time needed to recycle while improving recycling volume, both of which contribute significantly to creating a circular economy.

Improved Transparency and Innovation

A combination of cloud, remote monitoring systems, analytics and IoT can give waste management companies a clear view of their processes and operations. Even a simple ERP system allows companies to lower their cost of operations via more efficient resource allocation, improved processes, and better collaboration across the value chain. Similarly, technology will enable workflows within an entire ecosystem to become more transparent in real-time – it’s easy to imagine how a blockchain-based marketplace platform that connects different players in the waste management industry could ensure traceable waste chains, improved disposal, and more accountability, and fairer remuneration.

Easier and More Accurate Sorting

When you think of automation, the manufacturing, BPO, and medical industries most often come to mind, but RPA use cases rapidly grow within waste management. Apple’s Daisy robot, for instance, disassembles over 1.2 million old iPhones a year, saving almost 48000 tons from ending up in a landfill9. Similarly, Poland-based Bin-e has developed an intelligent waste bin that automatically uses AI-image classification to sort recyclable waste into separate compartments. Not only does this eliminate human error and consumer carelessness in sorting, but the increased speed in materials processing can lower waste management costs by as much as 80%10. Better sorting practices directly impact recycling by improving recycling rates and reducing impurities in recyclable material, creating higher-value recycled goods at a lower cost.

Collection Vehicle Routing

Many waste collection firms operate a fleet of vehicles on preset weekly or daily routes. However, waste bins often take a variable time to fill, depending on the population density and neighbourhood demographics. Using a combination of bin sensors and GPS, digitally-enabled waste collection companies can track which bins are filled on a given day and optimize their collection routes accordingly11. This saves on fuel and time and lowers emissions significantly. Another potential AI-powered use case involves the deployment of autonomous (i.e., self-driving and collecting) dump trucks. However, that technology is likely at least a decade from being commercially viable at scale.

Improved Strategic Planning

By leveraging big data and analytics tools, waste management companies could chart out a more effective strategic vision, optimize their operational models, and inject more sustainable practices into the waste management process chain. This is essential to improve recycling rates, eliminate scale inefficiencies, and pave a path toward a sustainable circular economy.

In most cases, the cost of recycling a particular resource is fixed; however, prices for those recovered resources are at the mercy of market fluctuations. Better strategic and tactical insights can help waste companies prioritize materials for recycling operations based on the optimal market prices, ensuring a better bottom line.

Predictive Maintenance and Process Optimization

Industrial recycling equipment tends to be large, expensive and has many moving parts. Predictive maintenance via IoT sensors and connected machinery can help waste companies circumvent unnecessary repairs and increase equipment uptime.

Essential data that helps predict an upcoming breakdown is often a mix of structured and unstructured data (such as year of production, model, repair history, the operational environment, etc.) and can be hard to parse manually. AI-enabled predictive maintenance, however, takes all these factors into account when forecasting just how often an asset should be serviced or when a part will fail.

Improved Strategic Planning

One of the most pressing issues plaguing the global waste management sector is an ongoing shortage of low-cost labour12. Manual collection, sorting and administration are all labour-intensive tasks, but technology can change that. AI-powered sorting and processing can reduce the volume of workers needed to run waste management operations by optimizing waste collection patterns and sorting-at-source.

Using ERP systems to run operations at waste management firms can also slash the number of management personnel required while paving the way for LEAN management structures that offer faster decision-making.

Loved what you read?

Get practical thought leadership articles on AI and Automation delivered to your inbox

Loved what you read?

Get practical thought leadership articles on AI and Automation delivered to your inbox

The Future Of Waste Is Circular

From a circular economy perspective, digitalized waste management is a single step in a long chain of activities but is crucial to creating closed-loop production cycles. For governments, granular and well-documented waste management data is imperative to circular economic policy-making and urban planning, particularly given the accelerated pace of urbanization and population growth across the globe.

While this data collection may have been nearly impossible in the past, the continued development of big data, M2X communication, cloud technology and IoT hardware has made accurate waste management information gathering a genuine possibility. As a result, much of the initial moves toward circular economies will likely begin not with restructuring how we produce but how we can reuse. And for that to happen, digitalization in the waste industry is a necessary first step.

Additionally, digitalization is a win-win for both waste companies and municipal administration. Complex disposal and recycling operations are often funded by local or state bodies and must compete with education, telecom, utilities, and healthcare for budgetary allocations. By lowering the cost of waste management, digitalization helps waste management companies offer more competitive rates and win more lucrative contracts.

Disclaimer Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the respective institutions or funding agencies

References:

- https://www.worldbank.org/en/topic/urbandevelopment/brief/solid-waste-management

- https://www.pearson.com/uk/educators/higher-education-educators/program/Pearce-Economics-Natural-Resources-Environment/PGM515981.html?tab=overview

- https://onlinelibrary.wiley.com/doi/abs/10.1111/jiec.12754

- https://www.worldbank.org/en/topic/urbandevelopment/brief/solid-waste-management

- https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/frequent-questions-regarding-epas-facts-and#Findings

- https://journals.sagepub.com/doi/pdf/10.1177/0734242X211029173

- https://journals.sagepub.com/doi/pdf/10.1177/0734242X211029173

- https://www.cnet.com/tech/mobile/how-apples-daisy-iphone-recycling-robot-works/

- https://www.waste360.com/recycling/bin-e-creates-contactless-smart-bin

- https://www.iotforall.com/how-various-industries-approach-smart-waste-management%EF%BF%BC

- https://swana.org/docs/default-source/resources-documents/arf-documents/labor-shortage-in-solid-waste-collection.pdf